-

1,4 butynediol solid superior product

CAS:110-65-6

Chemical properties of butynediol: white orthorhombic crystal. Melting point 58 ℃, boiling point 238 ℃, 145 ℃ (2KPa), flash point 152 ℃, refractive index 1.450. Soluble in water, acid solution, ethanol and acetone, slightly soluble in chloroform, insoluble in benzene and ether.

Usage: butynediol can be used to produce butene glycol, butynediol, n-butanol, dihydrofuran, tetrahydrofuran γ- A series of important organic products such as butyrolactone and pyrrolidone can be further used to manufacture synthetic plastics, synthetic fibers (nylon-4), artificial leather, medicine, pesticides, solvents (N-methyl pyrrolidone) and preservatives. Butynediol itself is a good solvent and is used as a brightener in electroplating industry.

-

Pale yellow highly toxic liquid 1,4-butynediol

1,4-butynediol solid, chemical formula C4H6O2, white orthorhombic crystal. Soluble in water, acid, ethanol and acetone, insoluble in benzene and ether. It can irritate the mucous membrane, skin and upper respiratory tract of the eyes. In industry, 1,4-butynediol solid is mainly prepared by Reppe method, catalyzed by butynediol copper or copper bismuth catalyst, and prepared by reaction of acetylene and formaldehyde under pressure (1 ~ 20 bar) and heating (110 ~ 112 ° C). The crude butynediol is obtained through reaction, and the finished product is obtained through concentration and refining.

-

3-chloropropyne colorless highly toxic flammable liquid

3-chloropropyne is an organic compound with the structural formula ch ≡ cch2cl. The appearance is colorless flammable liquid. Melting point -78 ℃, boiling point 57 ℃ (65 ℃), relative density 1.0297, refractive index 1.4320. Flash point 32.2-35 ℃, almost insoluble in water and glycerol, miscible with benzene, carbon tetrachloride, ethanol, ethylene glycol, ether and ethyl acetate. It is obtained by reacting propargyl alcohol with phosphorus trichloride. Used as an intermediate in organic synthesis.

-

Highly toxic liquid superior product propargyl alcoho

Colorless, volatile liquid with pungent odor. It is easy to turn yellow when placed for a long time, especially when exposed to light. It is miscible with water, benzene, chloroform, 1,2-dichloroethane, ether, ethanol, acetone, dioxane, tetrahydrofuran and pyridine, partially soluble in carbon tetrachloride, but insoluble in aliphatic hydrocarbons.

-

Production of 1, 4-butanediol (BDO) by maleic anhydride method

There are two main processes for the production of BDO by maleic anhydride. One is the direct hydrogenation process of maleic anhydride developed by Mitsubishi Petrochemical and Mitsubishi Chemical in Japan in the 1970s, which is characterized by the simultaneous production of BDO, THF and GBL in the hydrogenation process of maleic anhydride. Products of different compositions can be obtained by adjusting the process conditions. The other is the gas esterification hydrogenation process of maleic anhydride developed by UCC Company and Davey Process Technology Company in the United Kingdom, which is developed from the low pressure carbonyl synthesis technology. In 1988, the re-evaluation of the process flow was completed and the industrial design was proposed. In 1989, THE TECHNOLOGY WAS TRANSFERRED TO DongSANG CHEMICAL COMPANY OF Korea AND DONGGU CHEMICAL Company OF Japan TO BUILD a 20,000-TON/year 1, 4-BUtanEDIOL INDUSTRIAL production PLANT.

-

1, 4-butanediol properties

1, 4-butanediol

Alias: 1, 4-dihydroxybutane.

Abbreviation: BDO,BD,BG.

English name: 1, 4-Butanediol; 1, 4 – butylene glycol; 1, 4 – dihydroxybutane.

The molecular formula is C4H10O2 and the molecular weight is 90.12. The CAS number is 110-63-4, and the EINECS number is 203-785-6.

Structural formula: HOCH2CH2CH2CH2OH.

-

Propargyl alcohol production process and market analysis

Propargyl alcohol (PA), chemically known as 2-propargyl alcohol-1-ol, is a colorless, moderately volatile liquid with an aromatic leaf odor. The density is 0.9485g/cm3, melting point: -50℃, boiling point: 115℃, flash point: 36℃, flammable, explosive: soluble in water, chloroform, dichloroethane, methanol, ethanol, ethyl ether, dioxane, tetrahydrofuran, pyridine, slightly soluble in carbon tetrachloride, insoluble in aliphatic hydrocarbon. Propargyl alcohol is an important chemical raw material, widely used in medicine, chemical industry, electroplating, pesticide, steel, petroleum and other fields.

-

A highly toxic laboratory chemical — propargyl alcohol

Propargyl Alcohol, molecular formula C3H4O, molecular weight 56. Colorless transparent liquid, volatile with pungent odor, toxic, serious irritation to the skin and eyes. An intermediate in organic synthesis. Mainly used for synthesis of antibacterial and anti-inflammatory drugs sulfadiazine; After partial hydrogenation, propylene alcohol can produce resin, and after complete hydrogenation, n-propanol can be used as raw material of anti-tuberculosis drug ethambutol, as well as other chemical and pharmaceutical products. Can inhibit acid to iron, copper and nickel and other metals corrosion, used as rust remover. Widely used in oil extraction. It can also be used as solvent, stabilizer of chlorinated hydrocarbons, herbicide and insecticide. It can be used for the production of acrylic acid, acrolein, 2-aminopyrimidine, γ-picauline, vitamin A, stabilizer, corrosion inhibitor and so on.

Other names: propargyl alcohol, 2-propargyl – 1-alcohol, 2-propargyl alcohol, propargyl alcohol acetylene methanol.

-

Application of butanediol in cosmetics

Butanediol, mainly acetylene and formaldehyde as raw materials. It is used as chain extender for the production of polybutylene terephthalate and polyurethane, and as an important raw material for tetrahydrofuran, γ-butyrolactone, medicine and organic synthesis. Because polybutylene terephthalate is a kind of polyester with good properties, the demand for engineering plastics is increasing rapidly.

-

Propargyl will polymerize and explode

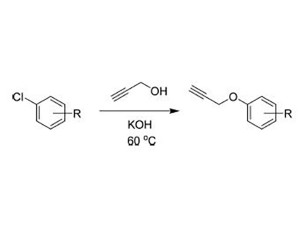

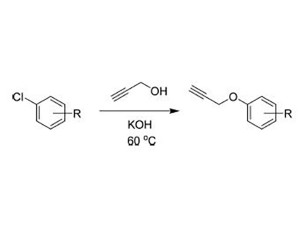

The initial process is based on propargyl alcohol as solvent, KOH as base, heating reaction to obtain the target. Reaction without solvent dilution conditions will be less impurities, the reaction is cleaner.

Considering the potential catalytic polymerization and explosive decomposition of the terminal alkynes, Amgen’s Hazard Evaluation Lab (HEL) stepped in to perform safety assessments and assist in process optimization before scaling up to 2 liters of the reaction.

DSC test shows that the reaction starts to decompose at 100 °C and release 3667 J/g energy, while propargyl alcohol and KOH together, although the energy drops to 2433 J/g, but the decomposition temperature also drops to 85 °C, and the process temperature is too close to 60 °C, safety risk is greater.

-

1,4-butanediol (BDO) and its preparation of biodegradable plastic PBAT

1, 4-butanediol (BDO); PBAT is a thermoplastic biodegradable plastic, which is a copolymer of butanediol adipate and butanediol terephthalate. It has the characteristics of PBA (polyadipate-1, 4-butanediol ester diol) and PBT (polybutanediol terephthalate). It has good ductility and elongation at break, as well as good heat resistance and impact performance. In addition, it has excellent biodegradability and is one of the most popular biodegradable materials in the research of biodegradable plastics and the best application in the market.

Products

Specializing in the production of propargyl alcohol, 1,4 butynediol and 3-chloropropyne