Products

Specializing in the production of propargyl alcohol, 1,4 butynediol and 3-chloropropyne

Propargyl alcohol production process and market analysis

Properties and applications of 2 propargyl alcohol

2.1 Excellent surface activity and dispersion

Propargyl alcohol has strong polarity and hydrophilicity, because it contains -OH, and hydrophobicity is because it contains hydrocarbon group, because these properties make propargyl alcohol as a non-ionic surfactant, showing excellent performance, with good low foaming, defoaming and wettability. Most wetting agents bubble easily, while most chemical defoaming agents have poor wettability. Compared with other surfactants, alkyl alcohols have small molecular weight, relatively easy diffusion, good dispersion, good wettability and low foam. On the one hand, alkyl alcohols contain hydrocarbon base branched chain groups, mostly small groups (generally methyl), there are two polar groups in the structure. Because of this chemical structure, alkyl alcohols have good wettability. On the other hand, alkyl-branched chains in propargyl alcohol can reduce the attraction between neighboring molecules and form a compressible and breathable expansion film at the gas-liquid boundary. Therefore, it not only does not form foam itself, but also has certain defoaming ability, and can be mixed with other defoaming agents to play a greater role.

2.2 Excellent metal corrosion inhibition

At present, the metal corrosion inhibitors used in acidic media are mostly organic compounds, which have strong adsorption capacity on metal surfaces. The molecular structure of propargyl alcohol includes polar groups and non-polar groups. It is an adsorbent of organic corrosion inhibitors. On the one hand, the coordination bonds formed between propargyl alcohol and metal atoms promote the adsorption of alcohol to a certain extent. At the same time, the PI bond in propargyl alcohol molecule is weakened, the triple bond is activated, and the polar hydroxyl group is close to the acetylene bond, which enhances the adsorption. In alkaline medium, proparynyl alcohol can adsorb Langmuir onto pure aluminum, which has good corrosion inhibition effect. Propargyl alcohol is because of its excellent performance, has a very wide range of uses, mainly used in pharmaceutical intermediates, copper or nickel plating polish, pesticide intermediate. In addition, propargyl alcohol can also be used as a corrosion inhibitor of high temperature, high pressure and high concentration hydrochloric acid in oil and natural gas Wells.

2.3 Application of propargyl alcohol

① Important intermediates in organic synthesis: in the pharmaceutical industry, proparynol is an important intermediate of sodium fosfomycin, calcium fosfomycin, sulfadiazine, and is also used in the production of allyl alcohol, acrylic, vitamin A and other pharmaceutical products; ② Electroplating industry brightener: propargyl alcohol compounds have good uniformity and glossiness, and good light resistance in nickel plating. Is a typical fourth generation nickel plating brightener, widely used in electroplating industry; ③ Important rust remover: proparynyl alcohol and its downstream compounds can inhibit the corrosion of iron, copper, nickel and other metals by acid substances such as acetic acid, phosphoric acid, sulfuric acid, hydrochloric acid; (4) Petroleum development: high temperature, high pressure and high concentration hydrochloric acid corrosion inhibitors are the key effective components of highly effective acid corrosion inhibitors in oil and gas Wells; ⑤ can be used as solvent, chlorinated hydrocarbon stabilizer, fungicide and other raw materials.

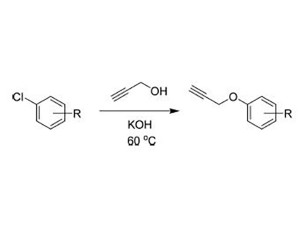

Production process

At present, the most widely used preparation method of propargyl alcohol at home and abroad is the reaction of formaldehyde and acetylene to produce propargyl alcohol and butynediol, which propargyl alcohol is a byproduct of butynediol. By adjusting the optimal intake volume of acetylene gas, improve the reaction pressure, determine the best pH value, the ratio of propargyl alcohol and butynediol can reach 1:1.6, so as to improve the selectivity of propargyl alcohol. Process: Add copper oxygenated catalyst into the activation tank, add softening water, stir for about 20min, and pour the mixture of catalyst and water into the stirring tank with a pump. The softened water and formaldehyde were added to the stirred tank to prepare the stirred solution containing 6%~10% formaldehyde. The stirring liquid was pumped into the reactor with a plunger feed pump according to the measured flow rate, and the acetylene compressor was started to adjust the acetylene flow rate and control the reaction speed. The automatic temperature and pressure control system of the reactor was started to control the temperature of the reactor at 90~130℃ and the pressure at (2.0±0.1) MPa. The reaction system circulates after discharge, and the discharge returns to the stirred tank. The content of formaldehyde in the material was detected after 0.5h. When the residual formaldehyde was less than 0.3%, the cycle was stopped and the reaction solution was pumped into an intermediate tank with propargyl and butanediol contents of about 4% and 6%, respectively. The catalyst in the production process needs to be replaced regularly, and the replacement period is 30 to 40 days. Nitrogen is used in conjunction with a catalyst to remove material from the system during replacement. After separation by pressure filtration, the remaining catalyst is placed in the spent catalyst storage tank and sealed with water. The new catalyst is written back into the next cycle of the batching system.

Propargyl alcohol market analysis

Dezhou Tianyu Chemical Co., Ltd. is one of the few domestic production of propargyl alcohol and butanediol large enterprises, the annual output of propargyl alcohol 1200T, butanediol 2400T, and the quality of Germany BASF equivalent. Henan Haiyuan Fine Chemical Co., Ltd. upgraded and optimized the project on the basis of the original production process of Shandong Dongfang Le, with an annual output of 1200T propionyl alcohol and 2400T butanediol. In China, proparynyl alcohol is mainly used in the synthesis of drugs, sodium phosphate, calcium phosphate, sulfonamide and pesticides, accounting for about 60% of the total. Rapid nickel plating and flash plating accounted for 17%. Oil production is about 10%; Steel's share is about 8 per cent; Other industries account for about 5%. Propargyl alcohol is a highly toxic chemical that is sensitive to production, marketing and use. It is downstream medicine, pesticide, metallurgical media and other fields of auxiliaries or one of the components. As of the end of 2017, the effective domestic production capacity was 4,770T /a, and the demand was about 4,948T /a. Supply and demand are basically balanced, with occasional periodic shortages.

Concludes

At present, the domestic propanol market competition is fierce, its biggest application field is the pharmaceutical industry fosfomycin series products, by the national antibiotic abuse supervision and electroplating industry environmental protection efforts, propanol downstream users in the short term basically did not increase. At present, we are trying to further optimize the new reaction process, constantly improve the yield of propargyl alcohol, and strive to reduce the energy consumption of propargyl alcohol products. The implementation of these works will further reduce the cost of propargyl alcohol products, improve the competitiveness of products, and strive to meet the domestic and foreign market demand for propargyl alcohol and series of products, to create more economic and social benefits.